Powerflex 700 Manual Fault Codes

Posted By admin On 24/05/19Apr 6, 2017 - Troubleshooting your Allen Bradley PowerFlex 700 AC drive begins with knowing what the displayed fault code indicates. 900 cau hoi thi nail phan 5. Fault 28 - See Manual - Encoderless TorqProve has been enabled but user has not read and. Troubleshooting your Allen Bradley PowerFlex 700 AC drive begins with knowing what the displayed fault. PowerFlex 700 Fault Codes. Fault 28 - See Manual.

Installation instructions manual - 96 pages

Technical data manual - 82 pages

Advertisement

Australian standard of living. Bookmark Creator Subjects;; Summary 'This Standard specifies procedures for the safety inspection and testing of low voltage single phase and polyphase electrical equipment, connected to the electrical supply by a flexible cord or connectig device, and that: is new equipment placed into service for the first time; is already in-service; has been serviced or repaired; is returning to service from a second-hand sale; or, is available for hire.

Also See for Allen-Bradley powerflex 700

Powerflex 4 Manual Fault Codes

Related Manuals for Allen-Bradley powerflex 700

- Controller Allen-Bradley PowerFlex 700 Installation Instructions ManualFrame 9 components replacement (84 pages)

- Controller Allen-Bradley PowerFlex 700 Installation Instructions ManualAdjustable frequency ac drive – frames 0..6 (78 pages)

- Controller Allen-Bradley PowerFlex 700 Installation Instructions ManualAdjustable frequency ac drive frames 7..10 (76 pages)

- Controller Allen-Bradley 1336 PLUS Selection ManualDigital ac drives in centerline motor control centers (26 pages)

- Water Pump Allen-Bradley PowerFlex 700 Installation Instructions ManualWith vector control option custom firmware (12 pages)

- Controller Allen-Bradley PowerFlex 700 Installation InstructionsStandard/vector control i/o wiring differences (2 pages)

- DC Drives Allen-Bradley PowerFlex 70 Quick Start QuideAdjustable frequency ac drive (18 pages)

Summary of Contents for Allen-Bradley powerflex 700

- Page 1 Adjustable Frequency AC Drive Series A Standard and Vector Control Firmware Versions Standard Control: xxx.x - 3.001 Vector Control: xxx.x - 3.002 User Manual www.abpowerflex.com..

- Page 2 Important User Information Solid state equipment has operational characteristics differing from those of electromechanical equipment. Safety Guidelines for the Application, Installation and Maintenance of Solid State Controls (Publication SGI-1.1 available from your local Rockwell Automation sales office or www.rockwellautomation.com/literature) describes some important differences between solid state equipment and hard-wired electromechanical devices.

- Page 3 • Series A - publication 20B-UM001x-xx-x • Series B - publication 20B-UM002x-xx-x Included is new information about using the PowerFlex 700 drive with an Auxiliary Control Power Supply (such as the 20-24V-AUX1). Place this document with your User Manual for future reference.

- Page 5 Summary of Changes The information below summarizes the changes to the PowerFlex 700 User Manual, publication 20B-UM001 since the last release. Manual Updates Change Page Bypass Attention statement added Catalog Number Explanation updated Mounting section updated Shield Termination description updated..

- Page 6 soc-ii Summary of Changes Notes:..

Page 7: Table Of Contents

Table of Contents Preface Overview Who Should Use this Manual? .P-1 What Is Not in this Manual .. . P-1 Reference Materials ..P-2 Manual Conventions .- Page 8 Table of Contents Appendix A Supplemental Drive Specifications... . . A-1 Communication Configurations .A-4 Information Output Devices .

Page 9: Who Should Use This Manual

What Is Not in this Manual The PowerFlex 700 User Manual is designed to provide only basic start-up information. For detailed drive information, please refer to the PowerFlex Reference Manual. The reference manual is included on the CD supplied with your drive or is also available online at http://www.rockwellautomation.com/literature.Page 10: Reference Materials

Allen-Bradley Drives Technical Support www.ab.com/support/abdrives Manual Conventions • In this manual we refer to the PowerFlex 700 Adjustable Frequency AC Drive as; drive, PowerFlex 700 or PowerFlex 700 Drive. • To help differentiate parameter names and LCD display text from other text, the following conventions will be used: –..Page 11: Drive Frame Sizes

Overview Drive Frame Sizes Similar PowerFlex 700 drive sizes are grouped into frame sizes to simplify spare parts ordering, dimensioning, etc. A cross reference of drive catalog numbers and their respective frame size is provided in Appendix General Precautions ATTENTION: This drive contains ESD (Electrostatic Discharge) sensitive parts and assemblies.Page 12: Catalog Number Explanation

Catalog Number Explanation The PowerFlex 700 catalog numbering scheme is shown on page P-5.- Page 13 Position 16➐ 17-18➐ 19-20➐ NN AD Drive Voltage Rating Rating Enclosure Documentation Brake Brake Resistor Emission Comm Slot Feedback Future Custom Firmware ➋ Code Type Code Enclosure Code Operator Interface Code w/Brake IGBT Code CE Filter CM Choke Code Type IP 20, Blank Cover None..

- Page 14 Overview Notes:..

Page 15: Installation/wiring

ATTENTION: The following information is merely a guide for proper installation. The Allen-Bradley Company cannot assume responsibility for the compliance or the noncompliance to any code, national, local or otherwise for the proper installation of this drive or associated equipment.Page 16: Mounting Considerations

Installation/Wiring Mounting Considerations Operating Temperatures PowerFlex 700 drives are designed to operate at 0° to 40° C ambient. To operate the drive in installations between 41° and 50° C, see below. Table 1.A Acceptable Surrounding Air Temperature & Required Actions Required Action .- Page 17 Wiring and Grounding Guidelines for PWM AC Drives (publication DRIVES-IN001). ATTENTION: PowerFlex 700 drives contain protective MOVs and common mode capacitors that are referenced to ground. These devices should be disconnected if the drive is installed on an ungrounded distribution system.

Page 18: General Grounding Requirements

Installation/Wiring General Grounding Requirements The drive Safety Ground - PE must be connected to system ground. Ground impedance must conform to the requirements of national and local industrial safety regulations and/or electrical codes. The integrity of all ground connections should be periodically checked. For installations within a cabinet, a single safety ground point or ground bus bar connected directly to building steel should be used.Page 19: Fuses And Circuit Breakers

Installation/Wiring Fuses and Circuit Breakers The PowerFlex 700 can be installed with either input fuses or an input circuit breaker. National and local industrial safety regulations and/or electrical codes may determine additional requirements for these installations. Refer to Appendix A for recommended fuses/circuit breakers.- Page 20 Installation/Wiring Shielded/Armored Cable Shielded cable contains all of the general benefits of multi-conductor cable with the added benefit of a copper braided shield that can contain much of the noise generated by a typical AC Drive. Strong consideration for shielded cable should be given in installations with sensitive equipment such as weigh scales, capacitive proximity switches and other devices that may be affected by electrical noise in the distribution system.

- Page 21 Installation/Wiring Location Rating/Type Description • Three tinned copper conductors with XLPE insulation. Standard Tray rated 600V, 90° C • 5 mil single helical copper tape (25% overlap min.) with (Option 2) (194° F) RHH/RHW-2 Anixter OLF-7xxxxx or three bare copper grounds in contact with shield. equivalent •..

- Page 22 Installation/Wiring AC Input Phase Selection (Frames 5 & 6 Only) ATTENTION: To avoid a shock hazard, ensure that all power to the drive has been removed before performing the following. Moving the “Line Type” jumper shown in Figure 1.2 will allow single or three-phase operation.

- Page 23 Installation/Wiring 1. Locate the small metal tab at the bottom of the end block. 2. Press the tab in and pull the top of the block out. Repeat for next block if desired. 3. Select appropriate transformer tap. 4. Replace block(s) in reverse order. Power Terminal Block Refer to Figure 1.3..

- Page 24 1-10 Installation/Wiring Figure 1.3 Typical Power Terminal Block Location ➌ DANGER Optional Optional Communications Use 75C Wire Only #10-#14 AWG Communications Module Torque to 7 in-lbs Module ➌ WIRE STRIP DC– 75C Cu Wire 6 AWG [10MM ] Max. 12 IN. LBS. PE B } TORQUE 1.4 N-M..

- Page 25 Installation/Wiring 1-11 Figure 1.4 Power Terminal Block Terminal Block DC– U (T1) V (T2) W (T3) R (L1) S (L2) * Note: T (L3) Shaded BR1 & BR2 Terminals will only be present on drives ordered with the Brake Option. DC–..

Page 26: Using Input/output Contactors

1-12 Installation/Wiring Terminal Description Notes DC Brake (+) DB Resistor Connection - Important: Only one DB resistor can be used with Frames 0-3. Connecting an DC Brake (–) internal & external resistor could cause damage. DC Bus (+) DC– DC Bus (–) PE Ground Refer to Figure 1.3..- Page 27 • Wiring AC line to drive output or control terminals. • Improper bypass or output circuits not approved by Allen-Bradley. • Output circuits which do not connect directly to the motor. Contact Allen-Bradley for assistance with application or wiring.

- Page 28 1-14 Installation/Wiring Figure 1.5 Typical Jumper Locations (see Table 1.D for description) ➌ ➍ PE 1 PE 2 MOV-PE JMPR PE 4 PE 3 DC FILTER CAP-PE JMPR WIRE STRIP 75C Cu Wire 6 AWG [10MM ] Max. 12 IN. LBS. n ly } TORQUE W ir..

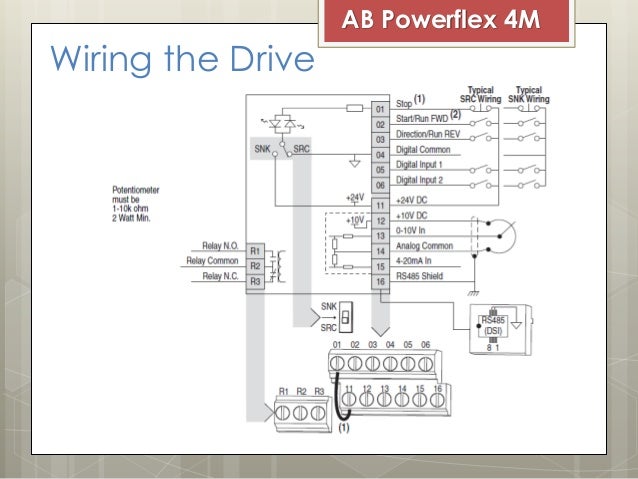

Page 29: I/o Wiring

Installation/Wiring 1-15 I/O Wiring Important points to remember about I/O wiring: • Use Copper wire only. Wire gauge requirements and recommendations are based on 75 degrees C. Do not reduce wire gauge when using higher temperature wire. • Wire with an insulation rating of 600V or greater is recommended. •..- Page 30 Figure 1.6 shows the I/O Control Cassette and terminal block locations. The cassette provides a mounting point for the various PowerFlex 700 I/O options. To remove the cassette, follow the steps below. Cassette removal will be similar for all frames (0 Frame drive shown).

- Page 31 Installation/Wiring 1-17 Figure 1.7 Standard Control Option I/O Terminal Designations Standard Control Option No. Signal Description Anlg Volts In 1 (–) Isolated , bipolar, differential, 320 - ±10V, 11 bit & sign, 88k ohm input Anlg Volts In 1 (+) impedance.

- Page 32 1-18 Installation/Wiring Figure 1.8 Vector Control Option I/O Terminal Designations Vector Control Option No. Signal Description Analog In 1 (–) Isolated , bipolar, differential, 320 - ±10V/4-20mA, 11 bit & sign, 88k Analog In 1 (+) ohm input impedance. For 4-20mA, Analog In 2 (–) a jumper must be installed at Analog In 2 (+)

- Page 33 Installation/Wiring 1-19 Encoder Terminal Block (Vector Control Option Only) Table 1.H Encoder Terminal Designations Description (refer to page A-3 for encoder specifications) See “Detail” in +12V DC Power Internal power source Figure 1.6 250 mA. +12V DC Return (Common) Encoder Z (NOT) Pulse, marker or registration input.

- Page 34 1-20 Installation/Wiring I/O Wiring Examples – Standard & Vector Control Options Input/Output Connection Example Required Parameter Changes • Adjust Scaling: Potentiometer Unipolar Speed Parameters 91/92 and 325/326 • View Results: Reference 10k Ohm Pot. Parameter 002 Recommended (2k Ohm Minimum) •..

- Page 35 Installation/Wiring 1-21 I/O Wiring Examples (continued) Input/Output Connection Example Required Parameter Changes • Configure with Parameter 340 Analog Output ±10V, 4-20 mA Bipolar • Select Source Value: +10V Unipolar (shown) Parameter 384, [Digital Out1 Sel] Standard Control • Adjust Scaling: 4-20 mA Unipolar + –..

Page 36: Reference Control

1-22 Installation/Wiring Reference Control “Auto” Speed Sources The drive speed command can be obtained from a number of different sources. The source is determined by drive programming and the condition of the Speed Select digital inputs, Auto/Manual digital inputs or reference select bits of a command word. The default source for a command reference (all speed select inputs open or not programmed) is the selection programmed in [Speed Ref A Sel].Page 37: Auto/manual Examples

Installation/Wiring 1-23 Auto/Manual Examples PLC = Auto, HIM = Manual A process is run by a PLC when in Auto mode and requires manual control from the HIM during set-up. The Auto speed reference is issued by the PLC through a communications module installed in the drive. Since the internal communications is designated as Port 5, [Speed Ref A Sel] is set to “DPI Port 5”..Page 38: Lifting/torque Proving

1-24 Installation/Wiring Lifting/Torque Proving For Lifting/Torque Proving details, refer to page C-2. Common Bus/Precharge Notes The following notes must be read and understood. Also refer to pages through 1-11 for additional common bus information. Important Application Notes 1. If drives without internal precharge are used (Frames 5 & 6 only), then: a) precharge capability must be provided in the system to guard against possible damage, and..Page 39: Emc Instructions

Installation/Wiring 1-25 EMC Instructions CE Conformity Conformity with the Low Voltage (LV) Directive and Electromagnetic Compatibility (EMC) Directive has been demonstrated using harmonized European Norm (EN) standards published in the Official Journal of the European Communities. PowerFlex Drives comply with the EN standards listed below when installed according to the User and Reference Manual.- Page 40 Essential Requirements for CE Compliance Conditions 1-6 listed below must be satisfied for PowerFlex drives to meet the requirements of EN61800-3. 1. Standard PowerFlex 700 CE compatible Drive. 2. Review important precautions/attention statements throughout this manual before installing the drive.

Page 41: Prepare For Drive Start-up

Chapter Start Up This chapter describes how you start up the PowerFlex 700 Drive. Refer Appendix B for a brief description of the LCD HIM (Human Interface Module). For information on . . . See page . . . Prepare For Drive Start-Up..Page 42: Status Indicators

Start Up Applying Power to the Drive ❏ 4. Apply AC power and control voltages to the drive. If any of the six digital inputs are configured to “Stop – CF” (CF = Clear Fault) or “Enable,” verify that signals are present or reconfigure [Digital Inx Sel].Page 43: Start-up Routines

Start Up Start-Up Routines The PowerFlex 700 is designed so that start up is simple and efficient. If you have an LCD HIM, three methods are provided, allowing the user to select the desired level needed for the application. • S.M.A.R.T. Start..Page 44: Running S.m.a.r.t. Start

Running S.M.A.R.T. Start During a Start Up, the majority of applications require changes to only a few parameters. The LCD HIM on a PowerFlex 700 drive offers S.M.A.R.T. start, which displays the most commonly changed parameters. With these parameters, you can set the following functions:..Page 45: About Parameters

Chapter Programming and Parameters Chapter 3 provides a complete listing and description of the PowerFlex 700 parameters. The parameters can be programmed (viewed/edited) using an LCD HIM (Human Interface Module). As an alternative, programming can also be performed using DriveExplorer™ or DriveExecutive™..- Page 46 Programming and Parameters ➊ ➋ ➌ ➍ ➎ ➏ Parameter Name & Description Values 198 [Load Frm Usr Set] Default: “Ready” Loads a previously saved set of Options: “Ready” parameter values from a selected user “User Set 1” set location in drive nonvolatile memory “User Set 2”..

Page 47: How Parameters Are Organized

Control Options Standard Control Two different control options are Option available for the PowerFlex 700; Standard and Vector. The Standard Control option provides typical Volts per Hertz and Sensorless Vector operation. The Vector Control option provides the added capability of FVC Vector control.- Page 48 Programming and Parameters Basic Parameter View – Standard Control Option Parameter 196 [Param Access Lvl] set to option 0 “Basic.” File Group Parameters Monitor Metering Output Freq Commanded Freq 002 Output Current M o n it DC Bus Voltage Motor Control Motor Data Motor NP Volts Motor NP RPM..

- Page 49 Programming and Parameters Basic Parameter View – Vector Control Option Parameter 196 [Param Access Lvl] set to option 0 “Basic.” File Group Parameters Monitor Metering Output Freq Commanded Speed002 Commanded Torque**024 M o n it Output Current Torque Current DC Bus Voltage Motor Control Motor Data Motor NP Volts..

- Page 50 Programming and Parameters Advanced Parameter View – Standard Control Option Parameter 196 [Param Access Lvl] set to option 1 “Advanced.” File Group Parameters Monitor Metering Output Freq Output Voltage MOP Frequency Commanded Freq 002 Output Power DC Bus Voltage Output Current Output Powr Fctr 008 DC Bus Memory 013 M o n it..

- Page 51 Programming and Parameters File Group Parameters Utility Direction Config Direction Mode HIM Ref Config Save HIM Ref U ti li ty Man Ref Preload 193 MOP Config Save MOP Ref MOP Rate Drive Memory Param Access Lvl 196 Save To User Set 199 Voltage Class Reset To Defalts 197 Reset Meters..

- Page 52 Programming and Parameters Advanced Parameter View – Vector Control Option Parameter 196 [Param Access Lvl] set to option 1 “Advanced.” File Group Parameters Monitor Metering Output Freq Torque Current MOP Reference Commanded Speed 002 Flux Current DC Bus Voltage Ramped Speed Output Voltage DC Bus Memory 013 M o n it..

- Page 53 Programming and Parameters File Group Parameters Dynamic Stop/Brake Stop/Brk Mode 155,156 Bus Reg Ki* Bus Reg Kd* Control Modes DC Brk Lvl Sel Bus Reg Mode 161,162 Flux Braking continued DC Brake Level DB Resistor Type 163 DB While Stopped 145 DC Brake Time Bus Reg Kp* D y n a m..

- Page 54 3-10 Programming and Parameters Basic Fan/Pump Parameter View – Standard Control Option Parameter 196 [Param Access Lvl] set to option 3 “Fan/Pump.” File Group Parameters Monitor Metering Output Freq Elapsed MWh Commanded Freq 002 Elapsed Run Time 010 Output Current DC Bus Voltage M o n it Output Power..

- Page 55 Programming and Parameters 3-11 Advanced Fan/Pump Parameter View – Standard Control Option Parameter 196 [Param Access Lvl] set to option 4 “Adv Fan/Pump.” File Group Parameters Monitor Metering Output Freq Elapsed Run Time 010 Commanded Freq 002 DC Bus Voltage Output Current Analog In1 Value 016 M o n it..

Page 56: Monitor File

3-12 Programming and Parameters Monitor File Parameter Name & Description Values page 3-2 for symbol descriptions 001 [Output Freq] Default: Read Only Output frequency present at T1, T2 & T3 Min/Max: –/+[Maximum Freq] (U, V & W) Units: 0.1 Hz [Commanded Freq] Default: Read Only..- Page 57 Programming and Parameters 3-13 Parameter Name & Description Values page 3-2 for symbol descriptions [MOP Frequency] Default: Read Only Standard Value of the signal at MOP (Motor Min/Max: –/+[Maximum Freq] Operated Potentiometer). Units: 0.1 Hz [MOP Reference] Default: Read Only Vector See description above.

Page 58: Motor Control File

3-14 Programming and Parameters Parameter Name & Description Values page 3-2 for symbol descriptions 026 [Rated kW] Default: Read Only Drive power rating. Min/Max: 0.00/3000.00 kW Units: 0.01 kW 027 [Rated Volts] Default: Read Only The drive input voltage class (208, 240, Min/Max: 0.0/6553.5 VAC 400 etc.).- Page 59 Programming and Parameters 3-15 Parameter Name & Description Values page 3-2 for symbol descriptions 045 [Motor NP Power] Default: Based on Drive Rating Set to the motor nameplate rated power. Min/Max: 0.00/100.00 Units: 0.00/1000.00 Vector 0.01 kW/HP [Mtr NP Pwr Units] [Mtr NP Pwr Units] Default: Drive Rating Based..

- Page 60 3-16 Programming and Parameters Parameter Name & Description Values page 3-2 for symbol descriptions 055 [Maximum Freq] Default: 110.0 or 130.0 Hz Sets the highest frequency the drive will Min/Max: 5.0/420.0 Hz output. Refer to [Overspeed Limit], 083. Units: 0.1 Hz 056 [Compensation] Enables/disables correction options.

- Page 61 Programming and Parameters 3-17 Parameter Name & Description Values page 3-2 for symbol descriptions 061 [Autotune] Default: “Calculate” Provides a manual or automatic method Options: “Ready” for setting [IR Voltage Drop], [Flux “Static Tune” Current Ref] and [Ixo Voltage Drop]. Valid “Rotate Tune”..

- Page 62 3-18 Programming and Parameters Parameter Name & Description Values page 3-2 for symbol descriptions [Autotune Torque] Default: 50.0% Vector Specifies motor torque applied to the Min/Max: 0.0/150.0% motor during the flux current and inertia Units: 0.1% tests performed during an autotune. [Inertia Autotune] Default: “Ready”..

- Page 63 Programming and Parameters 3-19 Parameter Name & Description Values page 3-2 for symbol descriptions [Torque Setpoint] Default: 0.0% Vector [Torque Setpoint1] Vector v3 Min/Max: –/+800.0% Provides an internal fixed value for Units: 0.1% Torque Setpoint when [Torque Ref Sel] is set to “Torque Setpt.”..

- Page 64 3-20 Programming and Parameters Parameter Name & Description Values page 3-2 for symbol descriptions [Motor NP Volts] × 0.25 071 [Break Voltage] Default: Sets the voltage the drive will output at Min/Max: 0.0/[Motor NP Volts] [Break Frequency]. Refer to parameter Units: 0.1 VAC 083 [Overspeed Limit].

Page 65: Speed Command File

Programming and Parameters 3-21 Parameter Name & Description Values page 3-2 for symbol descriptions [Notch Filter K] Default: 0.3 Hz Vector Sets the gain for the 2-pole notch filter. Min/Max: 0.1/0.9 Hz Units: 0.1 Hz [Marker Pulse] Default: Read Only Vector Latches the raw encoder count at each Min/Max:..- Page 66 3-22 Programming and Parameters Parameter Name & Description Values page 3-2 for symbol descriptions [Speed Mode] Default: “Open Loop” Standard Sets the method of speed regulation. Options: “Open Loop” “Slip Comp” “Process PI” [Feedback Select] Default: “Open Loop” Vector Selects the source for motor speed Options: “Open Loop”..

- Page 67 Programming and Parameters 3-23 Parameter Name & Description Values page 3-2 for symbol descriptions [Skip Frequency 1] Default: 0.0 Hz [Skip Frequency 2] Default: 0.0 Hz [Skip Frequency 3] Default: 0.0 Hz Sets a frequency at which the drive will Min/Max: –/+[Maximum Speed] not operate.

- Page 68 3-24 Programming and Parameters Parameter Name & Description Values page 3-2 for symbol descriptions 090 [Speed Ref A Sel] Default: “Analog In 2” Selects the source of the speed Options: “Analog In 1” thru reference to the drive unless [Speed Ref “Analog In 2”..

- Page 69 Programming and Parameters 3-25 Parameter Name & Description Values page 3-2 for symbol descriptions 096 [TB Man Ref Sel] Default: “Analog In 1” Sets the manual speed reference source Options: “Analog In 1” when a digital input is configured for “Analog In 2”..

- Page 70 3-26 Programming and Parameters Parameter Name & Description Values page 3-2 for symbol descriptions [Trim % Setpoint] Default: 0.0% Vector v3 Adds or subtracts a percentage of the Min/Max: –/+200.0% speed reference or maximum speed. Units: 0.1% Dependent on the setting of [Trim Out Select], parameter 118.

- Page 71 Programming and Parameters 3-27 Parameter Name & Description Values page 3-2 for symbol descriptions Important: Parameters in the Process PI Group are used to enable and tune the PI Loop. In order to allow the PI Loop to control drive operation, program the following: Standard Control Option –..

- Page 72 3-28 Programming and Parameters Parameter Name & Description Values page 3-2 for symbol descriptions 128 [PI Feedback Sel] Default: “Analog In 2” thru Selects the source of the PI feedback. Options: [PI Reference Sel]. 129 [PI Integral Time] Default: 2.00 Secs thru Time required for the integral component Min/Max:..

- Page 73 Programming and Parameters 3-29 Parameter Name & Description Values page 3-2 for symbol descriptions 137 [PI Error Meter] Default: Read Only thru Present value of the PI error. Min/Max: –/+100.0% –/+200.0% Units: 0.1% 138 [PI Output Meter] Default: Read Only thru Present value of the PI output.

- Page 74 3-30 Programming and Parameters Parameter Name & Description Values page 3-2 for symbol descriptions [Kp Speed Loop] Default: Vector Controls the proportional error gain of the Min/Max: 0.0/200.0 speed regulator. The drive automatically Units: adjusts [Kp Speed Loop] when a non-zero value is entered for [Speed Desired BW] or an auto-tune is performed.

Page 75: Dynamic Control File

Programming and Parameters 3-31 Dynamic Control File Parameter Name & Description Values page 3-2 for symbol descriptions [Accel Time 1] Default: 10.0 Secs [Accel Time 2] 10.0 Secs Sets the rate of accel for all speed Min/Max: 0.1/3600.0 Secs increases. 0.0/3600.0 Secs Units: 0.1 Secs..- Page 76 3-32 Programming and Parameters Parameter Name & Description Values page 3-2 for symbol descriptions [Droop RPM @ FLA] Default: 0.0 RPM Vector Selects amount of droop that the speed Min/Max: 0.0/200.0 RPM reference is reduced when at full load Units: 0.1 RPM torque.

- Page 77 Programming and Parameters 3-33 Parameter Name & Description Values page 3-2 for symbol descriptions 158 [DC Brake Level] Default: [Rated Amps] 0/[Rated Amps] × 1.5 Defines the DC brake current level Min/Max: injected into the motor when “DC Brake” (Equation yields is selected as a stop mode.

- Page 78 3-34 Programming and Parameters Parameter Name & Description Values page 3-2 for symbol descriptions 163 [DB Resistor Type] Default: “Internal Res” “None” Vector Selects whether the internal or an external DB resistor will be used. Options: “Internal Res” “External Res” Important: In 0-3 Frame drives, only one “None”..

- Page 79 Programming and Parameters 3-35 Parameter Name & Description Values page 3-2 for symbol descriptions 169 [Flying Start En] Default: “Disabled” Enables/disables the function which Options: “Disabled” reconnects to a spinning motor at actual “Enabled” RPM when a start command is issued. Not required in FVC Vector mode when using an encoder.

- Page 80 3-36 Programming and Parameters Parameter Name & Description Values page 3-2 for symbol descriptions 178 [Sleep-Wake Mode] Default: “Disabled” Enables/disables the Sleep/Wake Options: “Disabled” function. Important: When enabled, the “Direct” (Enabled) following conditions must be met: “Invert” (Enabled) • A proper value must be programmed for [Sleep Level] &..

- Page 81 Programming and Parameters 3-37 Parameter Name & Description Values page 3-2 for symbol descriptions 179 [Sleep-Wake Ref] Default: “Analog In 2” Selects the source of the input controlling Options: “Analog In 1” the Sleep-Wake function. “Analog In 2” 180 [Wake Level] Default: 6.000 mA, 6.000 Volts Defines the analog input level that will..

Page 82: Utility File

3-38 Programming and Parameters Parameter Name & Description Values page 3-2 for symbol descriptions 186 [Power Loss Level] Default: Drive Rated Volts Sets the level at which the [Power Loss Min/Max: 0.0/999.9 VDC Mode] selection will occur. Units: 0.1 VDC The drive can use the percentages referenced in [Power Loss Mode] or a trigger point can be set for line loss detection as follows: = [DC Bus Memory] –..- Page 83 Programming and Parameters 3-39 Parameter Name & Description Values page 3-2 for symbol descriptions 192 [Save HIM Ref] Enables a feature to save the present frequency reference value issued by the HIM to Drive memory on power loss. Value is restored to the HIM on power up. 1 =Save at Power Down 0 =Do Not Save x =Reserved..

- Page 84 3-40 Programming and Parameters Parameter Name & Description Values page 3-2 for symbol descriptions 197 [Reset To Defalts] Default: “Ready” thru Resets parameters to factory defaults Options: “Ready” except [Language], [Param Access Lvl], “Factory” [Voltage Class] & [TorqProve Cnfg] “Low Voltage” (params 196, 201, 202 &..

- Page 85 Programming and Parameters 3-41 Parameter Name & Description Values page 3-2 for symbol descriptions 203 [Drive Checksum] Default: Read Only Provides a checksum value that indicates Min/Max: 0/65535 whether or not a change in drive Units: programming has occurred. 209 [Drive Status 1] Read Only Present operating condition of the drive.

- Page 86 3-42 Programming and Parameters Parameter Name & Description Values page 3-2 for symbol descriptions 212 [Drive Alarm 2] Read Only Alarm conditions that currently exist in the drive. 1 =Condition True 0 =Condition False x =Reserved Bit # 1 =Condition True 0 =Condition False x =Reserved * Vector firmware 3.001 &..

- Page 87 Programming and Parameters 3-43 Parameter Name & Description Values page 3-2 for symbol descriptions 215 [Last Stop Source] Default: Read Only Displays the source that initiated the Options: “Pwr Removed” most recent stop sequence. It will be “DPI Port 1-5” cleared (set to 0) during the next start “Reserved”..

- Page 88 3-44 Programming and Parameters Parameter Name & Description Values page 3-2 for symbol descriptions 220 [Motor OL Count] Default: Read Only Accumulated percentage of motor Min/Max: 0.0/100.0% overload. Continuously operating the Units: 0.1% motor over 100% of the motor overload setting will increase this value to 100% and cause a drive fault.

- Page 89 Programming and Parameters 3-45 Parameter Name & Description Values page 3-2 for symbol descriptions 229 [Alarm 1 @ Fault] Read Only Captures and displays [Drive Alarm 1] at the time of thru the last fault. 1 =Condition True 0 =Condition False x =Reserved Bit # * Vector firmware 3.001 &..

- Page 90 3-46 Programming and Parameters Parameter Name & Description Values page 3-2 for symbol descriptions 238 [Fault Config 1] Enables/disables annunciation of the listed faults. 1 =Enabled 0 =Disabled x =Reserved Bit # * Vector firmware 3.001 & later Factory Default Bit Values 240 [Fault Clear] Default: “Ready”..

- Page 91 Programming and Parameters 3-47 Parameter Name & Description Values page 3-2 for symbol descriptions [Fault 1 Time] Default: Read Only [Fault 2 Time] Min/Max: 0.0000/429496.7295 Hr [Fault 3 Time] 0.0000/214748.3647 Hr [Fault 4 Time] Units: 0.0001 Hr [Fault 5 Time] [Fault 6 Time] [Fault 7 Time] [Fault 8 Time]..

- Page 92 3-48 Programming and Parameters Parameter Name & Description Values page 3-2 for symbol descriptions [Scale1 In Value] Default: Vector [Scale2 In Value] Vector Min/Max: –/+32000.0 [Scale3 In Value] Vector v3 –/+32767.0 (v2.xxx) [Scale4 In Value] Vector v3 –/+32767.000 Displays the value of the signal being Units: sent to [ScaleX In Value] using a link.

Page 93: Communication File

Programming and Parameters 3-49 Communication File Parameter Name & Description Values page 3-2 for symbol descriptions [DPI Data Rate] Default: “125 kbps” Standard Sets the baud rate for attached drive Options: “125 kbps” peripherals. When changing this value “500 kbps” the drive must be reset for the change to take affect.- Page 94 3-50 Programming and Parameters Parameter Name & Description Values page 3-2 for symbol descriptions [DPI Port Sel] Default: “DPI Port 1” Vector Selects which DPI port reference value Options: “DPI Port 1-5” will appear in [DPI Port Value]. [DPI Port Value] Default: Read Only Vector..

- Page 95 Programming and Parameters 3-51 Parameter Name & Description Values page 3-2 for symbol descriptions 278 [Jog Mask] [Logic Mask]. thru Controls which adapters can issue jog commands. 279 [Direction Mask] [Logic Mask]. thru Controls which adapters can issue forward/reverse direction commands. 280 [Reference Mask] [Logic Mask].

- Page 96 3-52 Programming and Parameters Parameter Name & Description Values page 3-2 for symbol descriptions 291 [Direction Owner] [Stop Owner]. thru Adapter that currently has exclusive control of direction changes. 292 [Reference Owner] [Stop Owner]. thru Adapter that has the exclusive control of the command frequency source selection.

Page 97: Inputs & Outputs File

Programming and Parameters 3-53 Parameter Name & Description Values page 3-2 for symbol descriptions [Data In C1] - Link C Word 1 [Data In A1] - Link A Word 1 [Data [Data In C2] - Link C Word 2 In A2] - Link A Word [Data In D1] - Link D Word 1 [Data In A1] - Link A Word 1 [Data [Data In D2] - Link D Word 2..- Page 98 3-54 Programming and Parameters Parameter Name & Description Values page 3-2 for symbol descriptions [Analog In 1 Hi] Default: 10.000 Volt [Analog In 2 Hi] 10.000 Volt Sets the highest input value to the analog Min/Max: 4.000/20.000mA input x scaling block. 0.000/20.000mA –/+10.000V [Anlg In Config], parameter 320 defines if..

- Page 99 Programming and Parameters 3-55 Parameter Name & Description Values page 3-2 for symbol descriptions [Analog Out1 Sel] Default: 0 “Output Freq” [Analog Out2 Sel] Vector Options: See Table Selects the source of the value that drives the analog output. [Analog Out1 Lo] Value Options [Analog Out1 Hi] Value Param.

- Page 100 3-56 Programming and Parameters Parameter Name & Description Values page 3-2 for symbol descriptions [Anlg Out1 Scale] Default: Vector v3 [Anlg Out2 Scale] Vector v3 Min/Max: [Analog Out1 Sel] Sets the high value for the range of Units: 0.01 analog out scale. Entering 0.0 will disable this scale and max scale will be used.

- Page 101 Programming and Parameters 3-57 Parameter Name & Description Values page 3-2 for symbol descriptions [Digital In1 Sel] Default: “Stop – CF” [Digital In2 Sel] Default: “Start” [Digital In3 Sel] Default: “Auto/ Manual” [Digital In4 Sel] Default: “Speed Sel 1” [Digital In5 Sel] Default: “Speed Sel 2”..

- Page 102 3-58 Programming and Parameters Parameter Name & Description Values page 3-2 for symbol descriptions [Dig Out Setpt] Vector v3 Sets the digital output value from a communication device. Example Set [Data In B1] to “379.” The first three bits of this value will determine the setting of [Digital Outx Sel] which should be set to “30, Param Cntl.”..

Page 103: Applications File

Programming and Parameters 3-59 Parameter Name & Description Values page 3-2 for symbol descriptions [Dig Out1 OnTime] Default: 0.00 Secs [Dig Out2 OnTime] 0.00 Secs [Dig Out3 OnTime] Vector Min/Max: 0.00/600.00 Secs Sets the “ON Delay” time for the digital Units: 0.01 Secs outputs.- Page 104 3-60 Programming and Parameters Parameter Name & Description Values page 3-2 for symbol descriptions [Spd Dev Band] Default: 2.0 Hz Vector v3 60.0 RPM Defines the allowable difference between the commanded frequency and encoder Min/Max: 0.1/15.0 Hz feedback value. A fault will occur when 3.0/450.0 RPM the difference exceeds this value for a Units:..

Page 105: Parameter Cross Reference - By Name

Programming and Parameters 3-61 Parameter Cross Reference – by Name Parameter Name Number Group Page Parameter Name Number Group Page Decel Owner Masks & Owners 3-52 Accel Mask Masks & Owners 3-51 Decel Time X 142, 143 Ramp Rates 3-31 Accel Owner Masks &..- Page 106 3-62 Programming and Parameters Parameter Name Number Group Page Parameter Name Number Group Page Fault Amps Diagnostics 3-44 Motor OL Factor Motor Data 3-15 Fault Bus Volts Diagnostics 3-44 Motor OL Hertz Motor Data 3-15 Fault Clear Faults 3-46 Motor Poles Motor Data 3-15 Fault Clear Mode..

- Page 107 Programming and Parameters 3-63 Parameter Name Number Group Page Parameter Name Number Group Page Save HIM Ref HIM Ref Config 3-39 Total Inertia Speed Regulator 3-30 Save MOP Ref MOP Config 3-39 Trim % Setpoint Speed Trim 3-26 Save To User Set Drive Memory 3-40 Trim Hi..

Page 108: Parameter Cross Reference - By Number

3-64 Programming and Parameters Parameter Cross Reference – by Number Number Parameter Name Group Page Number Parameter Name Group Page Output Freq Metering 3-12 Feedback Select Spd Mode & Limits 3-22 Commanded Freq Metering 3-12 Speed Mode Spd Mode & Limits Commanded Speed Metering Minimum Speed Spd Mode &..- Page 109 Programming and Parameters 3-65 Number Parameter Name Group Page Number Parameter Name Group Page 155, 156 Stop Mode X Stop/Brake Modes 3-32 234, 236 Testpoint X Sel Diagnostics 3-45 Stop/BRK Mode X Stop/Brake Modes 235, 237 Testpoint X Data Diagnostics 3-45 DC Brk Lvl Sel Stop/Brake Modes..

- Page 110 3-66 Programming and Parameters Number Parameter Name Group Page Number Parameter Name Group Page 323, 326 Analog In X Lo Analog Inputs 3-54 Spd Dev Band Torq Proving 3-60 324, 327 Analog In X Loss Analog Inputs 3-54 SpdBand Integrat Torq Proving 3-60 Anlg Out Config..

Page 111: Troubleshooting

Chapter Troubleshooting Chapter 4 provides information to guide you in troubleshooting the PowerFlex 700. Included is a listing and description of drive faults (with possible solutions, when applicable) and alarms. For information on… See page… Faults and Alarms Drive Status..Page 112: Drive Status

Troubleshooting Drive Status The condition or state of your drive is constantly monitored. Any changes will be indicated through the LEDs and/or the HIM (if present). Front Panel LED Indications Figure 4.1 Typical Drive Status Indicators ➊ POWER POWER S.M.A.R.T. Exit Lang Auto / Man Remove..- Page 113 Troubleshooting Precharge Board LED Indications Precharge Board LED indicators are found on Frame 5 & 6 drives. The LEDs are located above the “Line Type” jumper shown in Figure 1.2. Name Color State Description Power Green Steady Indicates when precharge board power supply is operational Alarm Yellow Flashing Number in “[ ]”..

Page 114: Manually Clearing Faults

Troubleshooting Manually Clearing Faults Step Key(s) 1. Press Esc to acknowledge the fault. The fault information will be removed so that you can use the HIM. 2. Address the condition that caused the fault. The cause must be corrected before the fault can be cleared. 3.- Page 115 Troubleshooting Fault Description Action ➂ Decel Inhibit The drive is not following a 1. Verify input voltage is within drive specified limits. commanded deceleration because it is attempting to limit 2. Verify system ground impedance bus voltage. follows proper grounding techniques.

- Page 116 Troubleshooting Fault Description Action ➀ HW OverCurrent The drive output current has Check programming. Check for exceeded the hardware current excess load, improper DC boost limit. setting, DC brake volts set too high or other causes of excess current. ➁ Incompat MCB-PB 106 Drive rating information stored on Load compatible version files into..

- Page 117 Troubleshooting Fault Description Action Output PhaseLoss 21 Current in one or more phases Check the drive and motor wiring. has been lost or remains below a Check for phase-to-phase continuity preset level. at the motor terminals. Check for disconnected motor leads. ➀..

- Page 118 Troubleshooting Fault Description Action ➀ Power Loss DC bus voltage remained below Monitor the incoming AC line for low voltage or line power interruption. ➂ 85% of nominal for longer than [Power Loss Time]. Enable/ Disable with [Fault Config 1] on page 3-46.

Page 119: Clearing Alarms

Troubleshooting Fault Description Action ➀ UnderVoltage DC bus voltage fell below the Monitor the incoming AC line for low voltage or power interruption. ➂ minimum value of 407V DC at 400/480V input or 204V DC at 200/240V input. Enable/Disable with [Fault Config 1] (page 3-46).Page 120: Alarm Descriptions

4-10 Troubleshooting Alarm Descriptions Table 4.C Alarm Descriptions and Actions Alarm Description ➀ Analog In An analog input is configured for “Alarm” on signal loss and signal loss has Loss occurred. ➁ Bipolar Parameter 190 [Direction Mode] is set to “Bipolar” or “Reverse Dis” and one Conflict or more of the following digital input functions is configured: “Fwd/Reverse,”..- Page 121 Troubleshooting 4-11 Alarm Description ➀ Drive OL The calculated IGBT temperature requires a reduction in Current Limit. If Level 2 [Drive OL Mode] is disabled and the load is not reduced, an overload fault will eventually occur. ➁ FluxAmpsRef The calculated or measured Flux Amps value is not within the expected Rang range.

- Page 122 4-12 Troubleshooting Alarm Description ➁ Occurs when: TB Man Ref • “Auto/Manual” is selected (default) for [Digital In3 Sel], parameter 363 Cflct Vector • [TB Man Ref Sel], parameter 96 has been reprogrammed. No other use for the selected analog input may be programmed. Example: If [TB Man Ref Sel] is reprogrammed to “Analog In 2,”..

Page 123: Common Symptoms/corrective Actions

Troubleshooting 4-13 Common Symptoms and Corrective Actions Drive does not Start from Start or Run Inputs wired to the terminal block. Cause(s) Indication Corrective Action Drive is Faulted Flashing red Clear fault. • Press Stop status light • Cycle power •..- Page 124 4-14 Troubleshooting Cause(s) Indication Corrective Action Incorrect reference source has None 3. Check [Speed Ref Source] for the source of been programmed. the speed reference. (See page 3-42) 4. Reprogram [Speed Ref A Sel] for correct source. (See page 3-24) Incorrect Reference source is None 5.

- Page 125 Troubleshooting 4-15 Stopping the drive results in a Decel Inhibit fault. Cause(s) Indication Corrective Action The bus regulation feature is Decel Inhibit fault 1. See Attention statement on page P-4. enabled and is halting deceleration screen. 2. Reprogram parameters 161/162 to due to excessive bus voltage.

Page 126: Testpoint Codes And Functions

4-16 Troubleshooting Testpoint Codes and Functions Select testpoint with [Testpoint x Sel], parameters 234/236. Values can be viewed with [Testpoint x Data], parameters 235/237. Values Description Units Minimum Maximum Default DPI Error Status Heatsink Temp 0.1 degC –100.0 100.0 Active Cur Limit 32767 Active PWM Freq 1 Hz..Page 127: Specifications

Appendix Supplemental Drive Information For information on . . See page . . Specifications Communication Configurations Output Devices Drive, Fuse & Circuit Breaker Ratings Dimensions A-15 Frame Cross Reference A-22 Specifications Category Specification Agency Listed to UL508C and CAN/CSA-C2.2 No. 14-M91. Certification ..- Page 128 Supplemental Drive Information Category Specification Protection Control Logic Noise Immunity: Showering arc transients up to 1500V peak (continued) Power Ride-Thru: 15 milliseconds at full load Logic Control Ride-Thru: 0.5 seconds minimum, 2 seconds typical Ground Fault Trip: Phase-to-ground on drive output Short Circuit Trip: Phase-to-phase on drive output Environment Altitude:..

- Page 129 Supplemental Drive Information Category Specification Control Frequency Control: Speed Regulation - w/Slip Compensation Standard (continued) (Volts per Hertz Mode) 0.5% of base speed across 40:1 Vector speed range 40:1 operating range 10 rad/sec bandwidth Speed Regulation - w/Slip Compensation Standard (Sensorless Vector Mode) 0.5% of base speed across 80:1 Vector..

Page 130: Communication Configurations

Supplemental Drive Information Communication Configurations Typical Programmable Controller Configurations Important: If block transfers are programmed to continuously write information to the drive, care must be taken to properly format the block transfer. If attribute 10 is selected for the block transfer, values will be written only to RAM and will not be saved by the drive.- Page 131 Supplemental Drive Information Logic Command/Status Words Figure A.1 Logic Command Word Logic Bits 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 Command Description x Stop 0 = Not Stop 1 = Stop (1)(2) Start 0 = Not Start..

- Page 132 Supplemental Drive Information Figure A.2 Logic Status Word Logic Bits 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 Status Description x Ready 0 = Not Ready 1 = Ready Active 0 = Not Active 1 = Active Command 0 = Reverse..

Page 133: Output Devices

Supplemental Drive Information Output Devices Common mode cores are internal to the drive. For information on output devices such as output contactors, cable terminators and output reactors refer to the PowerFlex Reference Manual. Drive, Fuse & Circuit Breaker Ratings The tables on the following pages provide drive ratings (including continuous, 1 minute and 3 second) and recommended AC line input fuse and circuit breaker information.- Page 134 Table A.A 208 Volt AC Input Protection Devices (See page A-13 for Notes) Dual Motor Input Element Time Non-Time Circuit Circuit 140M Motor Starter with Adjustable Current Drive (5)(6) Rating Freq. Temp. Ratings Output Amps Delay Fuse Delay Fuse Breaker Protector Range Catalog..

- Page 135 Table A.B 240 Volt AC Input Protection Devices (See page A-13 for Notes) Dual Motor Input Element Time Non-Time Circuit Circuit 140M Motor Starter with Adjustable Current Drive (5)(6) Rating Freq. Temp. Ratings Output Amps Delay Fuse Delay Fuse Breaker Protector Range Catalog..

- Page 136 Table A.C 400 Volt AC Input Protection Devices (See page A-13 for Notes) Dual Motor Input Element Time Non-Time Circuit Circuit 140M Motor Starter with Adjustable Current Drive (5)(6) Rating Freq. Temp. Ratings Output Amps Delay Fuse Delay Fuse Breaker Protector Range Catalog..

- Page 137 Table A.D 480 Volt AC Input Protection Devices (See page A-13 for Notes) Dual Motor Input Element Time Non-Time Circuit Circuit 140M Motor Starter with Adjustable Current Drive (5)(6) Rating Freq. Temp. Ratings Output Amps Delay Fuse Delay Fuse Breaker Protector Range Catalog..

- Page 138 Table A.E 600 Volt AC Input Protection Devices (See page A-13 for Notes) Dual Motor 140M Motor Starter with Adjustable Current Input Element Time Non-Time Circuit Circuit Drive (5)(6) Rating Freq. Temp. Ratings Output Amps Delay Fuse Delay Fuse Breaker Protector Range Catalog..

- Page 139 Table A.F 690 Volt AC Input Protection Devices Dual Motor Input Element Time Non-Time Circuit Circuit Drive Rating Freq. Temp. Ratings Output Amps Delay Fuse Delay Fuse Breaker Protector Catalog °C Number ND HD kHz Amps kVA Cont. 1 Min. 3 Sec. Min. Max.

- Page 140 A-14 Supplemental Drive Information Table A.G 540 Volt DC Input Protection Devices DC Input Drive Rating Ratings Output Amps Catalog Number ND HD Amps kW Cont. 1 Min. 3 Sec. Fuse Bussmann Style Fuse 540 Volt DC Input 20BC1P3 1 0.37 0.25 1.3 BUSSMANN_JKS-3 20BC2P1 1 0.75 0.55 2.1..

Page 141: Dimensions

BUSSMANN_JKS-300 150 – 204.1 132.2 180 BUSSMANN_JKS-400 Also applies to “J” voltage class. Dimensions Figure A.3 PowerFlex 700 Frames 0-3 (0 Frame Shown) 15.0 (0.59) see below 5.8 (0.23) dia. CAUTION HOT surfaces can cause severe burns 5.5 (0.22) - Frames 0-1 7.0 (0.28) - Frames 2-3..- Page 142 A-16 Supplemental Drive Information Figure A.4 PowerFlex 700 Frame 4 15.0 (0.59) 7.0 (0.28) dia. 7.0 (0.28) 3 Places Lifting Holes (0.31) 4 Places Dimensions are in millimeters and (inches) Approx. Weight kg (lbs.) Drive & A (Max.) C (Max.)

- Page 143 Supplemental Drive Information A-17 Figure A.5 PowerFlex 700 Frame 5 6.5 (0.26) 15.0 (0.59) 259.1 (10.20) 37.6 (1.48) Detail CAUTION HOT surfaces can cause severe burns Lifting Holes - 4 Places 6.5 (0.26) 12.7 (0.50) Dia. 12.5 (0.49) Dimensions are in millimeters and (inches).

- Page 144 A-18 Supplemental Drive Information Figure A.6 PowerFlex 700 Frame 6 8.5 (0.33) 18.0 (0.71) 49.6 (1.95) 360.6 (14.20) Detail Lifting Holes 8.5 (0.33) 126.3 4 Places (4.97) 13.5 (0.53) 12.7 (0.50) Dia. Dimensions are in millimeters and (inches) Approx. Weight kg (lbs.)

- Page 145 Supplemental Drive Information A-19 Figure A.7 PowerFlex 700 Bottom View Dimensions Frame Rating Dimensions 96.0 (3.78) 75.0 (2.95) 55.0 (2.17) 35.0 (1.38) 22.2 (0.87) Dia. – 4 Places 30.2 (1.19) 187.5 185.0 (7.38) (7.28) 132.9 (5.23) 41.9 (1.65) 56.1 (2.21) 75.9 (2.99)

- Page 146 A-20 Supplemental Drive Information Frame Rating Dimensions 105.3 (4.15) except 94.7 (3.73) 37.3 (1.47) Dia. 22.2 (0.87) Dia. 2 Places 50 HP, 28.7 (1.13) Dia. 2 Places 480V (37 kW, 400V) 184.5 165.1 (7.26) (6.50) 160.1 (6.30) 151.1 (5.95) 127.7 (5.03) 22.7 (0.89) 29.0 (1.14)

- Page 147 Supplemental Drive Information A-21 Frame Rating Dimensions 75 HP, 104.0 (4.09) 34.9 (1.37) Dia. 2 Places 22.2 (0.87) Dia. 480V 93.2 (3.67) 2 Places (55kW, 400V) 62.7 (2.47) Dia. Normal 2 Places Duty Drive 241.9 (9.52) 229.5 (9.04) 220.0 (8.66) 184.0 (7.24) 159.5..

Page 148: Frame Cross Reference

(4.59) 47.1 (1.85) 52.1 (2.05) 69.1 (2.72) 130.1 (5.12) 230.1 (9.06) 280.1 (11.03) 330.1 (13.00) Frame Cross Reference Table A.I PowerFlex 700 Frames AC Input DC Input 208/240 400V 480V 600V 540V 650V ND HP HD HP ND kW HD kW ND HP HD HP ND HP HD HP ND HP HD HP ND HP HD HP 0 0.5..Page 149: External And Internal Connections

External and Internal Connections B-1 Menu Structure LCD Display Elements Viewing and Editing Parameters ALT Functions Removing/Installing the External and Internal Connections The PowerFlex 700 provides a number of cable connection points (0 Frame shown). ➌ ➊ ➋ ➍ DANGER Use 75C Wire Only..Page 150: Lcd Display Elements

HIM is not the last controlling device and does not have Manual control of the drive. Allows value to be entered as an exponent (Not available on PowerFlex 700). Param # Allows entry of a parameter number for viewing/ +/–..Page 151: Menu Structure

Status Info View Fault Queue Drive Status 1 Device Items Clear Faults Drive Status 2 Device Version Clr Fault Queue PowerFlex 700 Drive Alarm 1 HIM Version Reset Device Product Data Drive Alarm 2 Main Control Board Speed Ref Source..- Page 152 HIM Overview Diagnostics Menu When a fault trips the drive, use this menu to access detailed data about the drive. Option Description Faults View fault queue or fault information, clear faults or reset drive. Status Info View parameters that display status information about the drive. Device Version View the firmware version and hardware series of components.

Page 153: Viewing And Editing Parameters

HIM Overview The PowerFlex 700 drive is initially set to Basic Parameter View. To view all parameters, set parameter 196 [Param Access Lvl] to option 1 “Advanced”. Parameter 196 is not affected by the Reset to Defaults function. Viewing and Editing Parameters..Page 154: Linking Parameters (vector Option Only

HIM Overview Linking Parameters (Vector Control Option Only) Most parameter values are entered directly by the user. However, certain parameters can be “linked,” so the value of one parameter becomes the value of another. For Example: the value of an analog input can be linked to [Accel Time 2].- Page 155 HIM Overview Table B.B Linkable Parameters Number Parameter Number Parameter Number Parameter DC Brake Time PI Feedback Hi Maximum Voltage Bus Reg Ki PI Feedback Lo Compensation Bus Reg Kp 476-494 ScaleX In Value Flux Up Mode Bus Reg Kd 477-495 ScaleX In Hi Flux Up Time Flying StartGain..

Page 156: Removing/installing The Him

HIM Overview Removing/Installing the HIM The HIM can be removed or installed while the drive is powered. Important: HIM removal is only permissible in Auto mode. If the HIM is removed while in Manual mode or the HIM is the only remaining control device, a fault will occur.Page 157: External Brake Resistor

Appendix Application Notes For information on . . See page . . For information on . . See page . . External Brake Resistor Process PI for Standard C-13 Control Lifting/Torque Proving Reverse Speed Limit C-16 Minimum Speed Skip Frequency C-17 Motor Control Technology Sleep Wake Mode..Page 158: Lifting/torque Proving

Application Notes Lifting/Torque Proving The lifting/torque proving feature of the PowerFlex 700 is intended for applications where proper coordination between motor control and a mechanical brake is required. Prior to releasing a mechanical brake, the drive will check motor output phase continuity and verify proper motor control (torque proving).- Page 159 Application Notes ATTENTION: To guard against personal injury and/or equipment damage caused by unexpected brake release, verify Digital Out 1 brake connections and/or programming. The default drive configuration energizes the Digital Out 1 relay when power is applied to the drive. If the brake is connected to this relay, it could be released.

- Page 160 Application Notes Rotate AutoTune Test ATTENTION: In this test the following conditions will occur: • The motor will be run for 12 seconds at base frequency (60 Hz). Note that equipment travel during this 12 second interval may exceed equipment limits. However, travel distance can be reduced by setting [Maximum Speed], parameter 82 to a value less than 45 Hz (i.e.

- Page 161 Contactor 24V configuration shown, see page 1-21 for other examples . Lifting/Torque Proving Application Programming The PowerFlex 700 lifting application is mainly influenced by parameters 600 through 611 in the Torque Proving group of the Application file. Figure C.3 and the paragraphs that follow describe programming.

- Page 162 Application Notes Torque Proving When the drive receives a start command to begin a lifting operation, the following actions occur: 1. The drive first performs a transistor diagnostic test to check for phase-to-phase and phase-to-ground shorts. A failure status from either of these tests will result in a drive fault and the brake relay will NOT be energized (brake remains set).

Page 163: Minimum Speed

Application Notes Speed Monitoring / Speed Band Limit This routine is intended to fault the drive if the difference between the speed reference and the encoder feedback is larger than the value set in [Spd Dev Band], parameter 602 and the drive is NOT making any progress toward the reference.Page 164: Motor Control Technology

Application Notes Motor Control Technology Within the PowerFlex family there are several motor control technologies: • Torque Producers • Torque Controllers • Speed Regulators Torque Producers Volts/Hertz This technology follows a specific pattern of voltage and frequency output to the motor, regardless of the motor being used. The shape of the V/Hz curve can be controlled a limited amount, but once the shape is determined, the drive output is fixed to those values.- Page 165 0.5% because they do not have connections for a feedback device. The PowerFlex 700 with the Vector Control option can offer better speed regulation by adding speed feedback. Using a speed feedback device (encoder) tightens speed regulation to 0.001% of base speed and extends..

Page 166: Motor Overload

C-10 Application Notes Motor Overload For single motor applications the drive can be programmed to protect the motor from overload conditions. An electronic thermal overload I function emulates a thermal overload relay. This operation is based on three parameters; [Motor NP FLA], [Motor OL Factor] and [Motor OL Hertz] (parameters 042, 048 and 047, respectively).Page 167: Overspeed

Application Notes C-11 [Motor NP FLA] is multiplied by [Motor OL Factor] to select the rated current for the motor thermal overload. This can be used to raise or lower the level of current that will cause the motor thermal overload to trip. The effective overload factor is a combination of [Motor OL Hertz] and [Motor OL Factor].Page 168: Power Loss Ride Through

C-12 Application Notes Allowable Output Frequency Range - Bus Regulation or Current Limit Allowable Output Frequency Range - Normal Operation Allowable Speed Reference Range Maximum Voltage Motor NP Voltage Frequency Trim due to Speed Overspeed Control Mode Limit Break Voltage Start Boost Boost..Page 169: Process Pi For Standard Control

Application Notes C-13 The PowerFlex 70 uses only these fixed percentages. The PowerFlex 700 can selectively use the same percentages or the user can set a trigger point for line loss detect. The adjustable trigger level is set using [Power..- Page 170 C-14 Application Notes It can operate as trim mode by summing the PI loop output with a master speed reference. Slip Comp Slip Adder Open Loop Linear Ramp Spd Ref Spd Cmd & S-Curve Process PI Ref Process PI Controller PI Fbk PI Enabled Speed Control..

- Page 171 Application Notes C-15 If no digital input is configured to “PI Enable,” then only the Bit 0 = 1 condition must be met. If the bit is permanently set to a “1”, then the loop will become enabled as soon as the drive goes into “run”. PI Enabled PI Pre-load Value PI Output..

Page 172: Reverse Speed Limit

C-16 Application Notes Reverse Speed Limit Figure C.6 [Rev Speed Limit], parameter 454 set to zero [Maximum Speed] Reverse Forward Speed Speed Minimum [Maximum Speed = 0 Speed] –10V [Maximum Speed] Minimum Speed ≠ 0 Reverse Forward Speed Speed Minimum [Maximum Speed ≠..Page 173: Skip Frequency

Application Notes C-17 Skip Frequency Figure C.8 Skip Frequency Frequency Command Frequency Drive Output Frequency Skip + 1/2 Band 35 Hz Skip Frequency 30 Hz Skip – 1/2 Band 25 Hz Time Some machinery may have a resonant operating frequency that must be avoided to minimize the risk of equipment damage.- Page 174 C-18 Application Notes Skip Frequency Examples The skip frequency will have Max. Frequency hysteresis so the output does not toggle between high and low values. Three distinct bands can be Skip Band 1 Skip Frequency 1 programmed. If none of the skip bands touch or overlap, each band has its own high/low limit.

Page 175: Sleep Wake Mode

Application Notes C-19 Sleep Wake Mode This function stops (sleep) and starts (wake) the drive based on separately configurable analog input levels rather than discrete start and stop signals. When enabled in “Direct” mode, the drive will start (wake) when an analog signal is greater than or equal to the user specified [Wake Level], and stop the drive when an analog signal is less than or equal to the user specified [Sleep Level].- Page 176 C-20 Application Notes Figure C.9 Sleep Wake Mode Is Sleep-Wake Working? Have these conditions been met? 1. [Sleep-Wake Ref] must be set to the analog input that will control 'Start/Stop' functions. Meet all Conditions! 2. [Sleep-Wake Mode] must = '1, Direct' (Enable) or '2, Invert (Enable).' 3.

Page 177: Start At Powerup

Application Notes C-21 Start At PowerUp Standard Control Option When Start At Powerup in 2 wire control is configured, the drive will start if the start permissive conditions are met within 10 seconds of drive power being applied. An alarm will be annunciated from application of power until the drive actually starts, indicating the powerup start attempt is in progress.Page 178: Stop Mode

C-22 Application Notes Stop Mode Mode Description Coast to Output Voltage Stop Output Current Motor Speed Time Coast Time is load dependent Stop Command This method releases the motor and allows the load to stop by friction. 1. On Stop, the drive output goes immediately to zero (off). 2.- Page 179 Application Notes C-23 Mode Description Ramp to Output Voltage Stop Output Current Motor Speed Output Current Output Voltage Hold Level Time DC Hold Time Stop Zero Command Command Speed This method uses drive output reduction to stop the load. 1. On Stop, drive output will decrease according to the programmed pattern from its present value to zero.

Page 180: Voltage Tolerance

C-24 Application Notes Voltage Tolerance Nominal Line Nominal Motor Drive Full Power Drive Operating Drive Rating Voltage Voltage Range Range 200-240 200* 200-264 180-264 208-264 230-264 380-400 380* 380-528 342-528 400-528 460-528 500-600 575* 575-660 432-660 (Frames 0-4 Only) 500-690 575* 575-660 475-759..- Page 181 Application Notes C-25 Notes:..

- Page 182 C-26 Application Notes Notes:..

- Page 183 Index Numerics , 4-12 Torq Prove Cflct , 4-12 UnderVoltage , 3-2 32 Bit Parameters , 4-12 VHz Neg Slope , 4-12 Waking , 3-47 Alarms Group , 4-9 Alarms, Clearing AC Input ALT Key , A-7 Circuit Breakers , B-2 Functions , 1-4 Ground..

- Page 184 Index-2 , 4-4 Cntl Bd Overtemp Fault , 3-49 Comm Control Group , 2-1 Before Applying Power , 3-12 Commanded Freq , 4-10 Bipolar Conflict Alarm , 3-12 Commanded Speed , 1-15 Bipolar Inputs , 3-13 Commanded Torque , 1-7 Bottom Plate Removal , 1-24 Common Bus..

- Page 185 , 3-13 Elapsed kWh , 1-2 Minimum Clearances , 3-12 Elapsed MWH Mounting , 3-12 Elapsed Run Time , A-15, A-17 PowerFlex 700 , 3-38 Direction Config Group , 1-25 Directive , 3-51 Direction Mask , 1-25 Instructions , 3-38..

- Page 186 Index-4 , 3-39 , 4-7 Fan/Pump Parameter Set Params Defaulted , 4-7 Phase Short , 4-1 Fault & Alarm Types , 4-7 Phase to Grnd , 3-47 Fault 1 Time , 4-7 Port 1-5 DPI Loss , 3-44 Fault Amps , 4-8 Power Loss , 3-44..

- Page 187 Index-5 , 1-5 Input , A-7 Ratings , 1-19 Hardware Enable , 4-5 Hardware Fault , 4-5 Heatsink OvrTemp Fault , P-3 General Precautions , B-4 HIM Menu Structure , 3-37 Gnd Warn Level HIM Menus , 4-5 Ground Fault , B-4 Diagnostics , B-4..

- Page 188 Index-6 , 3-39 MOP Config Group , 3-13 MOP Frequency , 3-30 Kf Speed Loop , 3-51 MOP Mask , 3-29 Ki Speed Loop , 3-52 MOP Owner , 3-30 Kp Speed Loop , 3-39 MOP Rate , 3-13 MOP Reference , 1-7 Motor Cable Lengths , 3-40..

- Page 189 Index-7 , 1-2 , 3-54 Operating Temperature Analog In x Hi , 3-54 Analog In x Lo , B-5 Operator Interface , 3-13 Analog Inx Value Output Contactor , 3-56 Analog Out Scale , 1-12 Start/Stop , 3-55 Analog Out1 Hi , 3-12 Output Current , 3-55..

- Page 190 Index-8 , 3-43 , 3-35 Dig In Status Flying StartGain , 3-58 , 3-37 Dig Out Setpt Gnd Warn Level , 3-43 , 3-18 Dig Out Status Inertia Autotune , 3-58 , 3-17 Dig Outx Level IR Voltage Drop , 3-59 , 3-17 Dig Outx OffTime Ixo Voltage Drop..

- Page 191 Index-9 , 3-39 , 3-23 Param Access Lvl Skip Freq Band , 3-29 , 3-23 PI BW Filter Skip Frequency x , 3-27 , 3-37 PI Configuration Sleep Level , 3-27 , 3-37 PI Control Sleep Time , 3-29 , 3-36 PI Deriv Time Sleep-Wake Mode , 3-29..

- Page 192 Trim In Select Access Panel , 3-26 , 1-7 Trim Lo General , 3-26 Trim Out Select , P-1 PowerFlex 700 Reference Manual , 3-40 Voltage Class , 2-1 Powering Up the Drive , 3-37 Wake Level , 3-34 Powerup Delay..

- Page 193 Index-11 , 3-23 , A-2 Rev Speed Limit Electrical , A-3 Encoder , C-16 Reverse Speed Limit , A-2 Environment , 3-19 Run Boost , A-1, A-2 Protection , 3-21 Speed Command File , 1-22 Speed Command Sources , 3-31 S Curve % , 3-30 Speed Desired BW..

- Page 194 Index-12 , 3-32 , 3-26 Stop Mode x Trim In Select , 3-51 , 3-26 Stop Owner Trim Lo , 3-32 , 3-26 Stop/Brake Modes Group Trim Out Select , 3-32 , 4-8 Stop/BRK Mode x Trnsistr OvrTemp Fault , 4-2 , 4-1 STS LED Troubleshooting..

- Page 195 PowerFlex 700 Parameter Record Number Parameter Name Setting Number Parameter Name Setting Motor Type PI Control Motor NP Volts PI Reference Sel PI Setpoint Motor NP FLA PI Feedback Sel Motor NP Hertz Motor NP RPM PI Integral Time Motor NP Power..

- Page 196 Number Parameter Name Setting Number Parameter Name Setting Save MOP Ref Encoder Z Chan MOP Rate 427, 431 Torque Ref X Sel Param Access Lvl 428, 432 Torque Ref X Hi Reset To Defalts 429, 433 Torque Ref X Lo Load Frm Usr Set Torq Ref A Div Save To User Set..

- Page 198 Rockwell Automation, 777 East Wisconsin Avenue, Suite 1400, Milwaukee, WI, 53202-5302 USA, Tel: (1) 414.212.5200, Fax: (1) 414.212.5201 Headquarters for Allen-Bradley Products, Rockwell Software Products and Global Manufacturing Solutions Americas: Rockwell Automation, 1201 South Second Street, Milwaukee, WI 53204-2496 USA, Tel: (1) 414.382.2000, Fax: (1) 414.382.4444..

Installation instructions manual - 96 pages

Technical data manual - 82 pages

Advertisement

Also See for Allen-Bradley powerflex 700

Related Manuals for Allen-Bradley powerflex 700

- Controller Allen-Bradley PowerFlex 700 Installation Instructions ManualFrame 9 components replacement (84 pages)

- Controller Allen-Bradley PowerFlex 700 Installation Instructions ManualAdjustable frequency ac drive – frames 0..6 (78 pages)

- Controller Allen-Bradley PowerFlex 700 Installation Instructions ManualAdjustable frequency ac drive frames 7..10 (76 pages)

- Controller Allen-Bradley 1336 PLUS Selection ManualDigital ac drives in centerline motor control centers (26 pages)

- Water Pump Allen-Bradley PowerFlex 700 Installation Instructions ManualWith vector control option custom firmware (12 pages)

- Controller Allen-Bradley PowerFlex 700 Installation InstructionsStandard/vector control i/o wiring differences (2 pages)

- Controller Allen-Bradley PowerFlex 700S Quick Start ManualAc drives - phase i control (framesizes 9 & 10) (52 pages)

Summary of Contents for Allen-Bradley powerflex 700

- Page 1 User Manual PowerFlex 700 AC Drives – Frames 0…10 Vector Control Firmware 4.001 and Up..

- Page 2 Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE). Allen-Bradley, DPI, DriveExplorer, DriveExecutive, Force Technology, PLC, PowerFlex, SCANport, Rockwell Software, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc. Trademarks not belonging to Rockwell Automation are property of their respective companies.

- Page 3 Description of New or Updated Information Page Removed the product certifications and specifications from Appendix A. All certification and specification information is located in the PowerFlex 700 Adjustable Frequency AC Drive Technical Data, publication 20B- TD001. Rockwell Automation Publication 20B-UM002G-EN-P - July 2014..

- Page 4 Summary of Changes Notes: Rockwell Automation Publication 20B-UM002G-EN-P - July 2014..

Page 5: Table Of Contents

Table of Contents Preface Who Should Use this Manual? ....9 What Is Not in this Manual.- Page 6 Table of Contents Appendix B HIM Overview External & Internal Connections .... . . 101 Removing/Installing the HIM.

- Page 7 Table of Contents Example 3: Five Step Positioner with Incremental Encoder .132 Power Loss Ride Through ....133 Process PID .

- Page 8 Table of Contents Rockwell Automation Publication 20B-UM002G-EN-P - July 2014..

Page 9: Preface

Frames 7…10 – publication 20B-IN014 Literature is available online at http://www.rockwellautomation.com/literature. • In this manual we refer to the PowerFlex 700 Adjustable Frequency AC Manual Conventions Drive as; drive, PowerFlex 700 or PowerFlex 700 Drive. • To help differentiate parameter names and LCD display text from other text, the following conventions will be used: –..Page 10: Additional Resources

Appendix Motors Drive Frame Sizes Similar PowerFlex 700 drive sizes are grouped into frame sizes to simplify spare parts ordering, dimensioning, etc. A cross reference of drive catalog numbers and their respective frame size is provided in the Catalog Number Explanation on..Page 11: General Precautions

The most common causes are: • Wiring AC line to drive output or control terminals. • Improper bypass or output circuits not approved by Allen-Bradley. • Output circuits which do not connect directly to the motor.- Page 12 Preface ATTENTION: The “adjust freq” portion of the bus regulator function is extremely useful for preventing nuisance overvoltage faults resulting from aggressive decelerations, overhauling loads, and eccentric loads. It forces the output frequency to be greater than commanded frequency while the drive's bus voltage is increasing towards levels that would otherwise cause a fault.

Page 13: Catalog Number Explanation

Preface Catalog Number Explanation c1…c5 Drive ND Rating ND Rating Code Type 400V, 50 Hz Input 480V, 60 Hz Input PowerFlex 700 Code Amps Frame Code Amps Frame 0.37 0.75 Voltage Rating Code Voltage Prechg. Frames 11.5 240V AC 0…6 15.4..- Page 14 Preface c1…c5 ND Rating Documentation Control & I/O 690V, 50 Hz Input Code Type Code Control I/O Volts ♦ Code Amps Frame Manual Standard 24V DC/AC ♦ No Manual Standard 115V AC Δ No Shipping Package (Internal Use Vector 24V DC Only) Δ..

Page 15: Programming And Parameters

Chapter Programming and Parameters This chapter provides a complete listing and description of the PowerFlex 700 parameters. The parameters can be programmed (viewed/edited) using an LCD HIM (Human Interface Module). As an alternative, programming can also be performed using DriveExplorer™ or DriveExecutive™ software and a personal computer.- Page 16 Chapter 1 Programming and Parameters Parameter Name & Description Values 198 [Load Frm Usr Set] Default: “Ready” Loads a previously saved set of parameter values Options: “Ready” from a selected user set location in drive “User Set 1” nonvolatile memory to active drive memory. “User Set 2”..

Page 17: How Parameters Are Organized

Programming and Parameters Chapter 1 How Parameters are The LCD HIM displays parameters in a File-Group-Parameter or Numbered List view order. To switch display mode, access the Main Menu, press ALT, then Organized Sel while cursor is on the parameter selection. In addition, using [Param Access Lvl], the user has the option to display the full parameter set (Advanced), commonly used parameters (Basic) or diagnostic/advanced tuning parameters..Page 18: Basic Parameter View

Chapter 1 Programming and Parameters Basic Parameter View Parameter 196 [Param Access Lvl] set to option 0 “Basic.” File Group Parameters Monitor Metering Output Freq Commanded Speed 002 M o n it Commanded Torque** 024 Output Current Torque Current DC Bus Voltage Motor Control Motor Data Motor NP Volts..Page 19: Advanced Parameter View

Programming and Parameters Chapter 1 Advanced Parameter View Parameter 196 [Param Access Lvl] set to option 1 “Advanced.” File Group Parameters Monitor Metering Output Freq Flux Current DC Bus Memory Commanded Speed 002 Output Voltage Analog In1 Value M o n it Ramped Speed Output Power Analog In2 Value..- Page 20 Chapter 1 Programming and Parameters File Group Parameters Utility Direction Config Direction Mode HIM Ref Config DPI Loss Action Save HIM Ref Man Ref Preload U til ity MOP Config Save MOP Ref MOP Rate Drive Memory Param Access Lvl Reset Meters Dyn UserSet Cnfg Reset To Defalts..

Page 21: Monitor File

Programming and Parameters Chapter 1 Monitor File Parameter Name & Description Values page 16 for symbol descriptions 001 [Output Freq] Default: Read Only Output frequency present at T1, T2 & T3 (U, V & Min/Max: –/+[Maximum Freq] Units: 0.1 Hz 002 [Commanded Speed] Default: Read Only..- Page 22 Chapter 1 Programming and Parameters Parameter Name & Description Values page 16 for symbol descriptions 018 [PTC HW Value] Default: Read Only Value present at the drive's PTC input terminals. Min/Max: –/+5.00 Volts Units: 0.01 Volts 021 [Spd Fdbk No Filt] Default: Read Only Displays the unfiltered value of the actual motor..

Page 23: Motor Control File

Programming and Parameters Chapter 1 Motor Control File Parameter Name & Description Values page 16 for symbol descriptions 040 [Motor Type] Default: “Induction” Set to match the type of motor connected. Options: “Induction” “Synchr Reluc” Important: Selecting option 1 or 2 also “Synchr PM”..- Page 24 Chapter 1 Programming and Parameters Parameter Name & Description Values page 16 for symbol descriptions 053 [Motor Cntl Sel] Default: “Sensrls Vect” Sets the method of motor control used in the Options: “Sensrls Vect” drive. “SV Economize” “Custom V/Hz” When “Adj Voltage” is selected, voltage control is “Fan/Pmp V/Hz”..

- Page 25 Programming and Parameters Chapter 1 Parameter Name & Description Values page 16 for symbol descriptions 057 [Flux Up Mode] Default: “Manual” Auto = Flux is established for a calculated time Options: “Manual” period based on motor nameplate data. [Flux Up “Automatic”..

- Page 26 Chapter 1 Programming and Parameters Parameter Name & Description Values page 16 for symbol descriptions 064 [Ixo Voltage Drop] Default: Based on Drive Rating Value of voltage drop across the leakage Min/Max: 0.0/230.0, 480.0, 575 VAC inductance of the motor at rated motor current. Units: 0.1 VAC Used only when parameter 53 is set to “Sensrls..

- Page 27 Programming and Parameters Chapter 1 Parameter Name & Description Values page 16 for symbol descriptions 437 [Neg Torque Limit] Default: –200.0% Defines the torque limit for the negative torque Min/Max: –800.0/0.0% reference value. The reference will not be Units: 0.1% allowed to exceed this value.

- Page 28 Chapter 1 Programming and Parameters Parameter Name & Description Values page 16 for symbol descriptions 413 [Encoder PPR] Default: 1024 PPR Contains the encoder pulses per revolution. For Min/Max: 2/20000 PPR improved operation in FVC Vector mode, PPR Units: 1 PPR should be ³..

Page 29: Speed Command File

Programming and Parameters Chapter 1 Speed Command File Parameter Name & Description Values page 16 for symbol descriptions 079 [Speed Units] Default: “Hz” Selects the units to be used for all speed related Options: “Hz” parameters. Options 0 & 1 indicate status only. 2 “RPM”..- Page 30 Chapter 1 Programming and Parameters Parameter Name & Description Values page 16 for symbol descriptions [Skip Frequency 1] Default: 0.0 Hz [Skip Frequency 2] Default: 0.0 Hz [Skip Frequency 3] Default: 0.0 Hz Sets a frequency at which the drive will not Min/Max: –/+[Maximum Speed] operate.

- Page 31 Programming and Parameters Chapter 1 Parameter Name & Description Values page 16 for symbol descriptions 090 [Speed Ref A Sel] Default: “Analog In 2” Selects the source of the speed reference to the Options: “Analog In 1” … drive unless [Speed Ref B Sel] or [Preset Speed 1- “Analog In 2”..

- Page 32 Chapter 1 Programming and Parameters Parameter Name & Description Values page 16 for symbol descriptions 096 [TB Man Ref Sel] Default: “Analog In 1” Sets the manual speed reference source when a Options: “Analog In 1” digital input (parameter 361…366) is “Analog In 2”..

- Page 33 Programming and Parameters Chapter 1 Parameter Name & Description Values page 16 for symbol descriptions 108 [Jog Speed 2] Default: 10.0 Hz 300.0 RPM Sets the output frequency when Jog Speed 2 is selected. Min/Max: –/+[Maximum Speed] Units: 0.1 Hz 1 RPM 116 [Trim % Setpoint] Default:..

- Page 34 Chapter 1 Programming and Parameters Parameter Name & Description Values page 16 for symbol descriptions Important: Parameters in the Slip Comp Group are used to enable and tune the Slip Compensation Regulator. In order to allow the regulator to control drive operation, parameter 080 [Speed Mode] must be set to 1 “Slip Comp”.

- Page 35 Programming and Parameters Chapter 1 Parameter Name & Description Values page 16 for symbol descriptions 126 [PI Reference Sel] Default: “PI Setpoint” Selects the source of the PI reference. Options: “PI Setpoint” … “Analog In 1” Adjustable Voltage Mode. “Analog In 2” “Reserved”..

- Page 36 Chapter 1 Programming and Parameters Parameter Name & Description Values page 16 for symbol descriptions 132 [PI Upper Limit] Default: +[Maximum Freq] 100% Sets the upper limit of the PI output. … Min/Max: –/+400.0 Hz –/+800.0% Units: 0.1 Hz 0.1% 133 [PI Preload] Default: 0.0 Hz..

- Page 37 Programming and Parameters Chapter 1 Parameter Name & Description Values page 16 for symbol descriptions 445 [Ki Speed Loop] Default: Controls the integral error gain of the speed Min/Max: 0.0/4000.0 regulator. The drive automatically adjusts [Ki Units: Speed Loop] when a non-zero value is entered for [Speed Desired BW] or an autotune is performed.

Page 38: Dynamic Control File

Chapter 1 Programming and Parameters Dynamic Control File Parameter Name & Description Values page 16 for symbol descriptions [Accel Time 1] Default: 10.0 Secs [Accel Time 2] 10.0 Secs Sets the rate of accel for all speed increases. Min/Max: 0.0/3600.0 Secs Max Speed Units: 0.1 Secs..- Page 39 Programming and Parameters Chapter 1 Parameter Name & Description Values page 16 for symbol descriptions 153 [Regen Power Limit] Default: –50.0% Sets the maximum power limit allowed to Min/Max: –800.0/0.0% transfer from the motor to the DC bus. When Units: 0.1% using an external dynamic brake, set this parameter to its maximum value.

- Page 40 Chapter 1 Programming and Parameters Parameter Name & Description Values page 16 for symbol descriptions [Bus Reg Mode A] “Adjust Freq” Default: [Bus Reg Mode B] “Both-Frq 1st” Sets the method and sequence of the DC bus Options: “Disabled” regulator voltage. Choices are dynamic brake, “Adjust Freq”..

- Page 41 Programming and Parameters Chapter 1 Parameter Name & Description Values page 16 for symbol descriptions 167 [Powerup Delay] Default: 0.0 Secs Defines the programmed delay time, in seconds, Min/Max: 0.0/10800.0 Secs before a start command is accepted after a power Units: 0.1 Secs 168 [Start At PowerUp]..

- Page 42 Chapter 1 Programming and Parameters Parameter Name & Description Values page 16 for symbol descriptions 178 [Sleep-Wake Mode] Default: “Disabled” Enables/disables the Sleep/Wake function. Options: “Disabled” Important: When enabled, the following “Direct” (Enabled) conditions must be met: “Invert” (Enabled) • A proper value must be programmed for [Sleep Level] &..

- Page 43 Programming and Parameters Chapter 1 Parameter Name & Description Values page 16 for symbol descriptions 182 [Sleep Level] Default: 5.000 mA, 5.000 Volts Defines the analog input level that will stop the Min/Max: 4.000 mA/[Wake Level] drive. 0.000 Volts/[Wake Level] Units: 0.001 mA 0.001 Volts..

Page 44: Utility File

Chapter 1 Programming and Parameters Utility File Parameter Name & Description Values page 16 for symbol descriptions 190 [Direction Mode] Default: “Unipolar” … Selects method for changing direction. Options: “Unipolar” “Bipolar” Mode Direction Change “Reverse Dis” … Unipolar Drive Logic Bipolar Sign of Reference Reverse Dis..- Page 45 Programming and Parameters Chapter 1 Parameter Name & Description Values page 16 for symbol descriptions 194 [Save MOP Ref] Enables/disables the feature that saves the present MOP frequency reference at power down or at stop. 1 = Save 0 = Do Not Save x = Reserved Bit # Factory Default Bit Values..

- Page 46 Chapter 1 Programming and Parameters Parameter Name & Description Values page 16 for symbol descriptions 201 [Language] Default: “Not Selected” Selects the display language when using an LCD Options: “Not Selected” HIM. This parameter is not functional with an “English” LED HIM.

- Page 47 Programming and Parameters Chapter 1 Parameter Name & Description Values page 16 for symbol descriptions 209 [Drive Status 1] Read Only Present operating condition of the drive. 1 = Condition True 0 = Condition False x = Reserved Bit # Bits Description Bits..